Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

The desire to have one's own profitable business is the obsession of many hired employees who day after day monotonously "shake the deadline" for an unbearable boss. However, to wish and do is two banks of the same river, which can be connected only by the right business idea. By the way, if you delve into the search, you can be surprised how many unrealized opportunities surround the world and the surrounding society. It is important only to be able to correctly look.

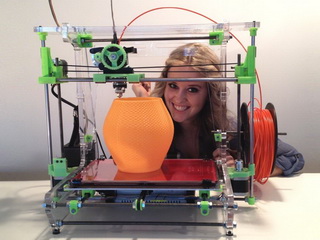

The following article will tell you about one affordable and easy way to earn money, which will help anyone to say goodbye to the bondage of a wage worker and take the path of independent entrepreneurial life. In business we will help 3D technology and its most progressive novelty is a 3d printer.

The concept and purpose of a 3D printer

The main feature of the 3d printer is its functional purpose. Unlike a conventional device that reproduces only printed texts or images, a 3d printer allows you to materialize voluminous objects. Such a result is possible due to the successive (layered) layering of the necessary volumetric form of multi-colored materials (plastic, wax or metal) against each other.

The main feature of the 3d printer is its functional purpose. Unlike a conventional device that reproduces only printed texts or images, a 3d printer allows you to materialize voluminous objects. Such a result is possible due to the successive (layered) layering of the necessary volumetric form of multi-colored materials (plastic, wax or metal) against each other.

With the help of this technical miracle, a plastic pistol was produced, which by its characteristics is in no way inferior to its combat prototype. And this result concerns not only external data, since the "printed" weapon successfully overcame all the test tests at the test site.

For start-up start-ups, whose investment opportunities are very limited, earnings for 3D printing is an excellent project. This is due to the fact that the modern market of technological novelties allows you to purchase a 3D printer at a reasonable price. So, you can find options where the amount of new equipment starts from $ 1,000. As for the necessary material (mainly plastic), the price range here is in the range of 1800-3300 rubles per kilogram.

When creating three-dimensional products, several different technologies are used, which are fundamentally different. The main among them are inkjet and laser printing.

Features of Inkjet Printing

· High pouring speed of the resulting shape of the product during cooling.

· Plastic solidifies due to the influence of ultraviolet light.

· It is possible to glue a powdery material (eg finely gutted pulp).

· When creating large-scale objects, it is possible to use thick mixtures of ceramic type.

Features of laser printing

· For fusing, laser technology is used (plastic or metal powder is melted).

· The lamination technology is applied (the final form of the figures being produced is formed as a result of gluing the layers).

· The final form of the object in the form of solid plastic is obtained as a result of using the technology of stereolithography. This means that the solidification of the liquid polymer is due to gradual illumination.

How to make money on the possibilities of a 3d printer?

Earnings due to the use of a 3d printer are diverse, since the produced items can be sold in a wide variety of industries and spheres of human leisure. Let's analyze in more detail some of the possible options.

Printing 3D images. In a constantly evolving world, human souvenir figures will look very relevant and attractive. Especially if they are miniature copies of friends, acquaintances or relatives. With a similar task, a 3d printer can handle quite easily. To do this, you just need to select the image of the three-dimensional shape for the given person, and then transfer the task to the printer. After that, human intervention ends, and the printing device creates a figure that completely copies the layout of the sent image.

Printing 3D images. In a constantly evolving world, human souvenir figures will look very relevant and attractive. Especially if they are miniature copies of friends, acquaintances or relatives. With a similar task, a 3d printer can handle quite easily. To do this, you just need to select the image of the three-dimensional shape for the given person, and then transfer the task to the printer. After that, human intervention ends, and the printing device creates a figure that completely copies the layout of the sent image.

If you look for already active projects on the Internet, you can meet a lot of entrepreneurs who copy images of famous actors, footballers, heroes of video games, cartoons and other famous characters in this way. Figures can be created for both mass sale and work individually with each client. A small feature of this production is that the finished products can be realized only after simple grinding procedures that do not take a lot of time.

A phone case created on a 3d printer.The manufacture of accessories deserves special attention, as the technology of 3d printer makes this process limited only by human imagination. The overwhelming majority of young people are obsessed with their own unique style, which is conveniently emphasized with the help of unique things. This list can contain: phone cases, original cases, keys and non-standard key chains, car trinkets, details that help to work and spend free time, and much, much more, what creative clientele will want.

A phone case created on a 3d printer.The manufacture of accessories deserves special attention, as the technology of 3d printer makes this process limited only by human imagination. The overwhelming majority of young people are obsessed with their own unique style, which is conveniently emphasized with the help of unique things. This list can contain: phone cases, original cases, keys and non-standard key chains, car trinkets, details that help to work and spend free time, and much, much more, what creative clientele will want.

If you take into account the profitability of an independent souvenir and accessory business, their combination with a 3d printer will allow an entrepreneur to quickly conquer the consumer market through an exclusive and high-quality product called "human fantasy".

For creative people, the meaning of which is the embodiment of unusual design solutions, 3d printer will act exactly as a link that will connect your favorite business with high profit.

Creating architectural layouts with the technology of a 3d printer.This business direction will be deeply appreciated by students and people whose lives are closely intertwined with architecture. This is due primarily to the fact that no colorful description will replace the material form of the future building, which can be implemented on a 3d printer. Such skilful presentation allows future and current architects to find profitable investors for their "live" projects, and the entrepreneur to expand the circle of his audience at the expense of grateful customers.

Creating architectural layouts with the technology of a 3d printer.This business direction will be deeply appreciated by students and people whose lives are closely intertwined with architecture. This is due primarily to the fact that no colorful description will replace the material form of the future building, which can be implemented on a 3d printer. Such skilful presentation allows future and current architects to find profitable investors for their "live" projects, and the entrepreneur to expand the circle of his audience at the expense of grateful customers.

Manufacturing of household items.Stamped factory items that can be found in almost every apartment have long been out of fashion.

The market requires exclusivity. Therefore, any client idea in itself is already a potential profit for the owner of the 3d printer. And it does not matter at all whether this is a gift vase or mug for everyday use. The main thing is to sell a well-embodied idea, which will be unique in its kind.

The market requires exclusivity. Therefore, any client idea in itself is already a potential profit for the owner of the 3d printer. And it does not matter at all whether this is a gift vase or mug for everyday use. The main thing is to sell a well-embodied idea, which will be unique in its kind.

Create silhouettes from photos.This idea belongs to an Australian designer who, with the help of photo processing skills and a 3d printer, was able to conquer the market of figurines around the world. The algorithm of his work was read as follows: he received an order from the client - he chose a good photo - created a silhouette - printed the received model on a 3d printer - sent the work to the client - he received a well-deserved reward. Everything is simple, it remains to acquire patience and start doing something you love.

Business plan earnings with a 3D printer

The success of any project, and printing on a 3d printer is no exception, depends primarily on the right organization. Therefore, a beginner entrepreneur should study all the nuances that can be like when buying a printer and related materials, or when working with the target audience during the sale of the final product.

The most effective business plan for earning on a 3d printer is to build according to the classical scheme, which has the following sequence of actions:

· Develop a calculation part that will include the cost of the initial equipment and the costs directed to its operation.

· Make a qualitative analysis of the market and compare the results with the expected profit. After this, it is necessary to take into account regular (monthly) expenses, which will be necessary for the full-fledged functioning of the project.

· Calculate the amount of monthly net income that will result from subtracting potential profits and monthly costs. The figure will reflect the indicator of profitability of the business.

· At all these stages, do not forget about advertising and active promotion of 3d printing services. After all, even super goods will not bring benefits, if no one learns about it.

And so it looks like an approximate financial and accounting part of the business plan:

· Legal expenses for registration of entrepreneurial activity (registration of unincorporated business activities).

· Purchase of 3d printer, examples you can see link - 150 000 rubles.

· Related (expendable) materials - 2400 rubles (the cost is taken for a kilogram of weight).

· A set of 10 bobbins of multi-colored plastic, which is recommended to be purchased in the following proportion: two units - black, three units - white, five units - at the discretion of the entrepreneur.

Thus, the estimated amount of the printer together with the materials is 174,000 rubles.

In addition to all of the above, you need a laptop, which in case of absence is definitely worth entering into the cost estimate. Its cost is heavily virified depending on the model and starts from 13,000 rubles.

Also do not forget that for a constant influx of customers just need a high-quality website that will contain unique selling texts and beneficial terms of cooperation. The total cost of an optimized site is about 30,000 rubles.

The monthly costs include the promotion of services in social networks and other Internet portals. The approximate figure here is about 6000 rubles.

The total amount of initial investment is 210000 rubles (printer, materials, laptop, advertising and site);

Monthly expenses - 18000 rubles (6000 rubles - advertising and promotion, 12000 rubles - purchase of consumables).

The estimated cost of a finished product made of plastic for 1 gram will be 50 rubles (or 50,000 rubles per kilogram). This condition is valid for the purchase of material at a price of 2,400 rubles per kilogram.

Potential profit

To calculate the maximum possible profit, which gives one 3d printer, the calculation will be carried out with the expectation that within 10 minutes the device is able to print 1 gram of the finished form. At the hour it will already bring about 300 rubles of profit. Suppose that the production process will take place round the clock, then the daily profit will be equal to 7200 rubles. Hypothetically, this figure per month can reach 220,000 rubles (the calculation is taken taking into account the continuous operation of the printer).

If you consider the side costs of plastic, which for this performance will be about five kilograms, then the total amount of profit is to deduct 12,000 rubles.

So, the potential profit with a continuously working printer, if you remove all current costs (6000 rubles advertising costs, 12,000 rubles for consumables and 10% tax) will be 180,000 rubles a month.

If, up to this point, the profitability of earnings with the help of a 3d printer caused doubts, then the elementary calculations were put in place. Despite the fact that this business plan implies continuous printing (which is impossible in life), the profit from less modest production standards also turns out to be significant. Indeed, it is rather difficult to meet projects with profitability, which in a month can reach not only 100%, but also 1000%.

It is worth recalling that the production profitability is understood as the ratio of the profit received from the sale of the final product to the expended amount that was spent to produce it. In the example above, profitability will be calculated using the following formula:

180000: 18000 = 10 rubles (profit for each ruble started in production). As a percentage, this figure is equal to 1000% of rubles.

All the calculations are approximate, but they also clearly reflect the ratio of possible profits to spent funds. If you properly hold a presentation of printing services for a 3d printer and attract the global capabilities of the Internet, you can get regular customers from all over the world. This will be a push, both to further development, and to the growth of a permanent source of income.

Probably, this is the question asked by a person who has learned about the availability of a 3d printer, but who has not yet decided what he needs. Without a doubt, a thing in the household is useful, he will say, but what exactly? Let's figure it out.

In fact, products on a 3d printer can be printed any . It is important only to choose the right material and printing technology. The use of plastic, photopolymer resins or ceramics makes it possible to produce souvenir products, ornaments, accessories, decorative objects, people's figures, models, toys, clichés, small parts for repairing almost any technique (especially if looking for original or too expensive, or laziness). If you want and have the inspiration and drawings, you can even print out any original tools, parts or whole techno-designers (for example, a fashionable prosthesis for your beloved grandfather or a scooter for yourself). It is necessary, however, tinker, but successful examples already exist.

There are ideas, but there is no possibility to embody them at home - do not despair! Many companies in Europe, and now with us, print products on the printer to order remotely according to the models you created.

What does 3d layout give?

Whoever had to spend a few days to create details for what seemed like the right drawings, and when installing to find a trivial mistake, he would not refuse the opportunity to check everything on the layout. This can be done, but it is only usually laborious, troublesome and expensive on materials. It kills any creative initiative.

3d prototyping finds an increasing application not only in design, but also in other industries. 3d printing layout allows you to more realistically imagine the project, look at it in a new way, identify inaccuracies and avoid them in the implementation.

Creation of new or, even more complicated, complementary elements, whether it's decor or auto parts , always has a certain risk. Even the best quality 3d model will not give you a complete idea of the subject in a particular environment. That's why some companies are actively using 3d printing models of new models before launching them in the production.

The relatively low cost of consumables for, even if repeated, printing a 3d layout minimizes the cost of developing models and improves their quality. And this reduces their cost and makes them competitive.

It will be useful for prototyping and graphic designers, especially for those who want to present their project profitable, whether it's a game character or a building plan. In this case, it is enough to order a 3d layout of the layout, and you will be a step ahead of the competitors, because the tangible is always closer and clearer.

The appearance of 3D printers in the market marked a new era. If earlier products developed on the basis of high technologies in the household economy allowed to solve usual problems, then in the case of 3D printing, a new way of using the devices is proposed. Of course, it is new only for the average user, since similar technologies have been used in industry and manufacturing enterprises for a long time. But in any case, printing on a 3D printer significantly expands the possibilities of the consumer, to the development of which, as practice shows, not all are ready. This is largely due to the complexity of the technological implementation of devices, as well as the nuances of their operation.

But the most interesting questions concern the benefits of such printers. What products allows you to create this device? For what purposes can its products be used? And how does a 3D printer work? These are important issues, since three-dimensional printing is still an expensive pleasure. Therefore, it is inadvisable to acquire the appropriate equipment for the sake of curiosity, to put it mildly. At the very least, it is worthwhile to look more closely into the working processes of printing and to find out what benefit can be expected from them.

What is a 3D printer?

This device for three-dimensional printing, through which you can generate three-dimensional objects that duplicate a pre-prepared virtual model of the object. Compared to traditional printers that output electronic text to paper, 3D devices provide the output of three-dimensional information, that is, they create objects with real physical parameters. In fact, in order to understand how a 3D printer works, you should consider the stages of making solid objects with it.

Principle of operation in general terms

Work begins with creating a virtual template on the computer using a special program. Next, the software processes the model in order to separate it into layers. After that, the technical part of the printer comes into operation, layer by layer forming a mass of composite powder for further fabrication of the object. As the special chamber is filled with material, the printer axis distributes the mass along the working surface. After the formation of each layer, the head of the device imposes an adhesive base. This process is repeated until the object developed in the program for printing is executed. It is important to consider that manufacturing on a 3D printer can be performed using different technologies. Accordingly, the printing technique, and the properties of the material used, as well as approaches to software implementation of the task, change.

Rapid prototyping technology

Despite the differences in the nuances of the manufacturing process, almost all devices for 3D printing work on the principle of rapid prototyping. In accordance with this concept, production is carried out by rapid formation of experimental models for preliminary demonstration of the possibilities of the future product. The technology was conceived back in the 1980s with the goal of creating samples and blanks. Today this method is known as additive production, understanding of which will give an answer to the question of how a 3D printer works and what distinguishes its function from traditional approaches to making objects. So, if in the process of milling, turning and material removal takes place, and forging, pressing and stamping change the shape of the workpiece, then additive production involves increasing the mass of the material by increasing the layers. In other words, the 3D printer changes the phase state of substances in certain boundaries of space. To date, three-dimensional printing is developing in several areas, among which we can identify stereolithography technology (STL), methods of applying thermoplastic (FDM) and laser sintering (SLS).

The method of layer-by-layer fusion of a thermoplastic

This, perhaps, is the most popular technique of three-dimensional manufacturing. The prevalence of FDM-devices is facilitated by several factors. First of all, relatively inexpensive plastics are used in the operation of devices. It is also important simple operation technique, which is especially important in working with such equipment. Typically, the technology of 3D-printers of this type include work with thermoplastics, one of which is polylactide. Among the advantages of this material is the ecological compatibility, since this plastic is obtained from sugar cane and corn.

The main element in the printer itself is an extruder that performs the task of the print head. However, in this part, not everything is so unambiguous, because the element is a complex of individual components. If we consider the term "extruder" in the usual sense, then only part of the head in the form of a feeding mechanism will apply to it. Either way, the printing substrate feeds the plastic for the 3D printer by applying a molten thread. Movement of the mechanical part is provided by an electric motor. As a result, the mechanism directs the thread into the heated nozzle tube, which forms the final object.

Stereolithographic installations

The technology of laser stereolithography today is widely used in dental prosthetics. This is the second most popular type of printers for 3D printing. A distinctive feature of stereolithographic devices is the reception of unsurpassed high quality of objects. Such results are achieved due to the resolution of the apparatus, which can be estimated by single microns. Therefore it is quite logical that the work of a 3D printer based on laser stereolithography is highly valued not only by dentists but also by jewelers. The software part of the device in many ways resembles FDM-analogs, but there are a number of features of the technology. Despite the fact that the principle of printing is called laser stereolithography, more often the function of such equipment is based on LED ultraviolet projectors.

Projector models are more reliable than laser ones and are cheaper at a price. They do not need delicate mirrors, which ensure the deflection of the rays, which simplifies the design. At the same time printing on a 3D printer with projectors is characterized by high performance. This advantage is achieved due to the fact that there is not a consistent, but a complete illumination of the contour of the layer.

Laser sintering

Another type of application of the laser method. In this case, light-alloy plastic is used. A powerful laser draws on the plastic base the cross section of the object, which leads to melting and sintering of the material. This happens with each layer until a complete model is prepared, which the program for the 3D printer has prepared as a workpiece. The remains of the plastic powder are shaken from the resulting object at the end of the working process. An essential disadvantage of such devices is the creation of objects with a porous surface. On the other hand, this does not affect the strength of the products. Moreover, the models that come out of such printers are the most durable. The installation itself has a complex design and, as a consequence, a high cost. In this case, and the manufacturing process takes a long time compared to other types of 3D printers. As noted by users, the speed of the formation of the model is several centimeters per hour.

Consumables

The main material for creating models by 3D printing is thermoplastic. In addition to the already mentioned varieties, it is worth noting the plastic for 3D-printer in the formats ABS and PLA. Nylon, polycarbonate, polyethylene and other types also used in industry are also used. At the same time, some installations permit mixing of materials, as well as the use of auxiliary substances that improve the qualitative characteristics of the future product. For example, for this purpose use which, in essence, is the same kind of PVA plastic. By dissolving it in water, the user can create complex geometric shapes.

The most exotic material for use in such problems is metal. To obtain such a product, 3D models are also used for printing on a 3D printer, and the differences in technology are reduced to a function. With it, a binding adhesive is applied to the places indicated by the computer program. Further on the entire working area the head is applied by a thin layer of metallic powder. That is, the metal does not melt, as in the case of plastics, but is superimposed and glued together layer by piece.

![]()

Controlling printer operation

To begin with, it is worth noting the operations that are controlled by the user through the computer. This is the adjustment of the temperature of the nozzle and the working platform, the rate of material supply and the work of the electric motor, which ensures the positioning of the print head. All these actions are under the control of electronic controllers. As a rule, modern models of such devices are based on the Arduino system with an open architecture. As for the programming language, the printers use the so-called G-code, built on the commands for managing the equipment for printing. At this stage, you can go to the review of software-slicers, which provide translation of the 3D-model for printing on a 3D printer in code that is easy to control. At once it is necessary to tell, that such software has no direct relation to development of graphic models.

Software

The list of the main tasks of the slicers includes setting parameters, according to which the printing will be carried out. The choice of a particular program is determined by the type of printer. For example, RepRap devices involve the use of open-source slicers. Among these are Replicator G and Skeinforge. However, there are many manufacturers who recommend using only proprietary software from specific companies. This, in particular, refers to the Cube devices from the company 3D Systems. As for product modeling, this is the special program for a 3D printer designed for 3D design. Usually CAD editors are used for these purposes, which, however, require some experience with 3D design.

What products can I get?

The range of capabilities of three-dimensional printers is actively expanding, which allows you to create products for a wide variety of market segments. If we talk about construction and architecture, it is very much appreciated the possibility of making mock-ups, for which, in fact, the concept of additive production was developed. In the engineering industry, a 3D printer is also widely used. Products in this case can be represented both consumer products, and individual elements for concepts. As already mentioned, the high precision of manufacturing parts was highly appreciated by medical workers. In addition to prosthetics, a 3D printer is used in the manufacture of mock-ups and specimens of organs.

3d technology makes life easier. They have almost completely occupied the place of drawings and calculations on paper. Special programs allow you to see the 3D model in all projections at the design stage, immediately check it and, if necessary, eliminate the shortcomings. They reduce the development time to several hours and virtually eliminate errors inherent in the creation models manually. Especially this applies to technology, where the manufacture of complex parts can take a long time.

Printing details on a 3d printer - new technology , able to fairly "strain" suppliers of supplies, and not only. Who faced with repairing equipment that has original elements, he knows the true price of the question and understands how difficult it is sometimes to find suitable parts, not even tools, to work with them.

Manufacturing details on a 3d printer is basically a copying of an existing object and its layer-by-layer formation from plastic or other material. For owners of 3d printers it is a magic wand, solving any problems of home repair. They literally print everything: small accessories, clips and clips, stands, dishes, decor elements, toys and designers.

All because 3d printing has a number of advantages:

Relative simplicity. There is a whole range of 3d editors (OpenSCAD, 3D Max), which allow you to create certain models suitable for printing with certain skills. The presence of a 3d scanner simplifies this task to a minimum.

2. The speed of execution. To create a product manually, it can take from a couple of days to a month (depending on the complexity). Manufacturing of parts on the printer 3d takes significantly less time, depending on the size, but usually within a day.

3. Cost is the cornerstone. In general, it depends on the type of printing and quality of consumables. 3d printing plastic parts or consumables according to statistics is more profitable than buying the original.

4. Originality and strict conformity. Many are familiar with the annoying breakdown of one part of the unit, which is sold only in the assembly. 3d printing of parts of machines and equipment allows us to reconstruct a specific required element according to strictly specified parameters, which is especially important in the design or restoration of mechanisms, parts of which are very difficult to find.

5. Quality. Eyewitnesses claim that the parts reconstructed by the printer with the correct density are not inferior to plastic originals.

to curtailThe use of the 3d printer makes it possible to print products for different consumer areas. Such a printer is an excellent find for a small business. He provided an opportunity for people to engage in a new profitable business. What ideas can be implemented by a 3d printer? With such a device, you can easily start small-scale production of a wide variety of consumer products.

To sell the produced goods, you can run an online store. This will allow the products to be sold at zero. Volumetric printing will allow people to realize their own ideas. Today, the latest inventions can be tested at home, without having a large seed capital.

Trade in three-dimensional mappings

3d printer is a revolutionary invention for the formation of a small home business. Thanks to this device, the realization of the production idea is now available to small businesses. Many creative people now have the best way to develop independently, and also earn good money on their favorite business.

3d printer is a revolutionary invention for the formation of a small home business. Thanks to this device, the realization of the production idea is now available to small businesses. Many creative people now have the best way to develop independently, and also earn good money on their favorite business.

When we are going to organize our own business in this area, we must take into account the increase in competition. Soon, 3d printer will become one of the elements of household appliances. This will definitely lead to special changes in the modern world. Accordingly, the number of consumers of 3D devices will increase significantly. To date, several sources of implementing three-dimensional images are already there. A year later the demand will increase, and thanks to this innovation the work of engineers and designers will cost much more.

For example, today people have a unique opportunity to congratulate on the birthday of old friends who live abroad via the Internet, communicate and at the same time see each other with the help of Skype. And soon they will be able to send gifts to each other through the Internet in the form of files with ready-made 3D models, which the birthday person can print at home on the printer. In this case, one such model can be sold many times.

For example, today people have a unique opportunity to congratulate on the birthday of old friends who live abroad via the Internet, communicate and at the same time see each other with the help of Skype. And soon they will be able to send gifts to each other through the Internet in the form of files with ready-made 3D models, which the birthday person can print at home on the printer. In this case, one such model can be sold many times.

You can earn money on both 3D printing and selling finished files for them. Trade 3d images - passive profit from the implementation of files for further processing in 3D. To be in the forefront with businessmen in this direction, now it is necessary to study the 3D design.

Business at home with a 3D printer

What you need to know when purchasing a 3D printer, if there is an idea to organize a small one:

- The cost. On the Internet there are various options for the price. But if you buy a 3d device to make a quality product for implementation, it is recommended to pay attention to printers from $ 1000. It is also worth considering the cost of consumables. Bobbins with a plastic thread, depending on its quality and color, can cost $ 35-55. You also need to look at the manufacturer. Today, quite a few such representatives who work officially, as a result of which there may be problems with spare parts.

- Limiting the parameters of the finished product. Inexpensive 3D printers can print products up to 12 cm3. A device costing $ 3000 can create elements of 30 cm3, weighing up to 5kg. It should be borne in mind that separately manufactured parts can be joined together. This criterion allows not to be limited to the parameters of the 3d elements produced by the device.

- Multicolored printing. To reproduce multi-colored volumetric models it is possible only on very expensive 3D devices. Printers have a number of print heads that work together. Such an idea for home business is not so important, you can save on it, you can paint details yourself if necessary. You can also play the product by individual elements, while for each one you simply change the color of the thread. After the individual parts are assembled into one product.

Improving 3d equipment for small business

The technological idea of printing 3D has become quite popular, intensively developing further. Today, of course, there are still minor shortcomings, for example, low print speed, a limitation in the parameters of the product. If you increase the need for goods made on the 3d printer, expand the business in this area, you can simultaneously use several devices at once. It should also be taken into account that the technology of three-dimensional printing, or rather, the equipment itself, is constantly being improved and is being finalized.

The technological idea of printing 3D has become quite popular, intensively developing further. Today, of course, there are still minor shortcomings, for example, low print speed, a limitation in the parameters of the product. If you increase the need for goods made on the 3d printer, expand the business in this area, you can simultaneously use several devices at once. It should also be taken into account that the technology of three-dimensional printing, or rather, the equipment itself, is constantly being improved and is being finalized.

Hewlett-Packard already has an idea of producing a modified model of a 3D printing device. It will produce the best 3d printer from the previous models, specialized for home business. The main advantage of the latest equipment can be noted:

- high speed of the printer;

- a relatively small cost - about 15 thousand dollars.

This cost of the product suggests the following - the company is focused on a small business using 3D printing. It will be very difficult for consumers to find products for marketing, when many will have their own 3D device at home.

Bulk printing is a promising idea for starting your own business.

To study the technology of 3D modeling is necessary today. A period of new opportunities is approaching. On expensive production 3D devices already print buildings in several floors. There will come a time when their cost will be available for small businesses.