Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

23213

Painting walls, floors, ceilings and other elements of the house or apartment can be different colors and different tools. One of the most popular and common tools for applying paints is a paint roller. About it and the story will go.

There are a lot of varieties of rollers and each of them is intended for a certain type of work. Distinctive paint rollers are not only in the field of application, but in size and material of the fur coat.

A few words about painting terms

A roller is a part of a tool consisting of a cylinder (plastic, wooden or aluminum) with a soft coat on it that absorbs the paint and then transfers it to the painted surface when rolling. A familiar design, consisting of a handle and a curved metal rod (clasp), on which the roller is mounted, is called a machine or simply a handle.

Now that we have understood the terminology, let's talk about the classification of rollers.

Domestic paint rollers are divided into four groups (GOST-10831-87 "Paint rollers - technical specifications") and each of them has its own lettering: the first letter is always B (roller), the second - determines the material from which its coat is made, and the third, if it exists, is the field of application.

So, the first three groups are designed for painting surfaces with paint and varnish composition: group VM - rollers with fur coating, the second - VMP - rollers with fur coating for coloring floors, the third - BMC - rollers with fur coating for painting concave angles. The last, the fourth group - VP - rollers with polyurethane foam (foam rubber) coating for work with water-adhesive compounds.

In accordance with GOST, the fur coating of the paint roller should be made of sheepskin or silk base covered with a pile of chemical threads.

Recently, a large number of different import rollers have appeared on sale. Their assortment is so great that it makes one even think of a specialist who has seen it. Different countries use their classification of rollers. For example, manufacturers of Finland divide rollers into 7 groups.

Mini-rollers are mainly used for painting small or hard-to-reach surfaces, including corners. Midi-rollers - one of the most common types of house painters. The difference between universal and professional platens is very conditional. The criterion for this division, as a rule, is the quality of the fur coat and the diameter of the rod. For professional tools is characterized by a higher quality of fur coat (they wear out much more slowly) and a rod diameter of 8 mm. Facade rollers characterize the presence of an internal intermediate packing and a more perfect bearing system. Due to this, in combination with the increased diameter, when working with such a tool, the roller rotates more slowly and as a result, the spraying of the paint is sharply reduced.

Wireframe rollers They are very convenient in work, since they easily curve around irregularities. In addition, they are 20-35% cheaper than traditional platens. The peculiarity of these rollers is indicated already in their name - the coat is not put on a cylinder of any material, like all the other structures, but on a special wire or polymer frame. Unfortunately, they are still little known in Russia.

Special rollers are divided into rollers for floor, wavy surfaces, aggressive and structural compositions, lamination and for wallpaper rolling.

But one of the leading manufacturers of tools for painting works firm ANZA (Sweden) uses a different classification. In size, these are three groups: mini-, midi-and maxi-rollers, and for application - five groups: high-quality PERFEKTA; for all types of repair (floors, walls, ceilings); for varnishes and enamels, when a very smooth coating surface is required; special and for simple works.

What is made of the fur coat for the roller

In addition to the dimensions of the paint tool, you must also pay attention to the material from which his coat is made. Here the situation is even more complicated, because to designate approximately the same materials of fur coats, different firms use their specific names. Here are the main groups of materials for fur coats and some of their names used by SOKEVA (Finland):

- group PE - polyester (polyester): foam rubber (moltoprene), vestan (artificial fur), yellow vestan (reinforced);

- group N - natural materials: sheep's fur, llama, goat, velor, mohair, felt, rubber;

- group PC - polyacryl: kanecaron, modacryl (kanekaron-filts), meril;

- group PA - polyamide: perlon, nylon.

Fur coats for simple work (from top to bottom):

Annon

Elon

Polyfoam foam

Styrofoam perforated

Polyester

Perlon

Dylen

Polar

Materials of fur coats for paint rollers (from top to bottom):

Rylon

Rylon

Sheepskin

Mohair with short pile

Terry cloth

Felt

Foam

Even fur coats made from one material can differ among themselves in other parameters. Here are just a few examples. Mini-rollers are made of several types of foam: normal and high-density with a density of 30 and 60 kg / m 3, respectively. Naturally, a denser roller lasts longer. Foam mini-rollers, used for high-quality painting with varnishes and water-dispersive paints, are available in two colors: dark blue (top quality) and thick yellow color. Polyacrylic rolls made of a material called melir, imitating lamb's fur, are available in three colors (in order of quality): blue, yellow and light green, and rolls made of perlon (polyamide) are white, light yellow and light green in color.

When choosing a roller, in addition to the material of the fur coat itself, you should pay attention to its compatibility with the lacquer-colored material that you are going to use. The stability of the coat to the effects of paint can be judged by the strips applied to it - the more of them, the more resistant the material to aggressive substances. In addition, the strip can determine the method of its manufacture and replaceability. If the stripes on the fur coat go along the roller, it means that it is sewn and it can be replaced. If they are located across or obliquely, the coat is glued and can not be replaced. Most of the fur coats for mini and midi-rollers are glued. They are not very durable, as paint and varnish materials quickly destroy glue. Rollers with glued fur coats are relatively cheap, because the process of their manufacture is less laborious. Fur coats for professional, universal, facade and special platens, as a rule, sewn. They last longer and, if necessary, they are replaced with new ones.

And to make it easier for you to navigate when choosing a roller, you can use the data of our table, in which the material of the fur coat and the permissible types of paintwork materials are correlated. The most resistant to the action of chemicals are coats made of polyamides and polyacrylics, they can be used for almost all commonly used paints and varnishes. The situation with polyesters is more difficult - they are suitable only for water-based, alkyd and oil paints. Not for all types of paints are suitable and fur coats from natural materials. The price of the platen ranges from $ 1.5 to $ 12-15, depending on the size, material and quality.

Finally a few words about the so-called texture rollers (for creating textured surfaces). They are produced quite a lot of varieties, each of which is designed for a certain type of work with textured (textural) decoration materials. With their help, you can roll a drawing on the prepared surface, get a coating of marble or "wild" stone and many other options.

In order not to be mistaken as the purchased tool for painting works, be guided by the availability of an international quality certificate ISO 9001.

And in conclusion, still need to say about the machines (handles) for rollers (price $ 1.5-15). They differ not only in size of the clasp, but also simply in the total length. There are short (about 30 cm), medium (40-45 cm) and long (more than 50 cm) lathes. If you need something to paint very high, then for this purpose special extension handles are produced. The length of these handles ranges from 0.7 to 4 m ($ 25-45).

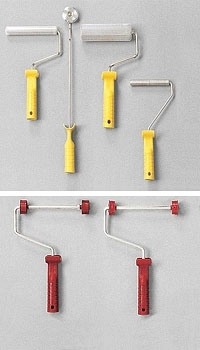

Above and below - aluminum frames and machines of the company ANZA.

There are several other elements that are designed to make the work with the roller more convenient and qualitative. Increasingly, pallets ($ 0.8-2), sets consisting of a roller with a pallet ($ 3-6), roller stands ($ 1.5-2) and scrapers ($ 0.3) can be found on the market for cleaning. In the pallet there is a place where the paint is poured, and a surface on which it is possible to pre-roll the roller to achieve its uniform impregnation.

Stand and tray for paint rollers of the company ANZA.

So before you start painting, pick up a suitable roller, get a pallet for paint and other necessary accessories, and then work will give you pleasure.

Do not seek to immediately use a roller of a very large size, it is rather difficult to work with them - it is difficult to achieve uniform coloring of the surface.

To paint the surface smoothly and without streaks, before the paint is applied to the wall, the roller should be well rolled on a special tray, and if it is not, then per sheet of perforated metal or, in extreme cases, cardboard or plywood. Then there will be as much paint on the roller as necessary.

If you want to use a roller to paint a different color than the one that was applied before, carefully roll it over a sheet of cardboard or plywood until you make sure that the previous color has disappeared. Then proceed to painting the surfaces.

Do not use the same roller to apply different types of paints, even if the roller has been well washed with an appropriate solvent.

If you need to protect the roller from drying for a few days, then carefully pack it in a whole plastic bag and tighten it tightly.

If it is necessary to store the roller for a long time (for several months), place it in a tin can, suitable for its length and diameter, fill it with paint and wrap it carefully in a plastic bag.

5 / 7

For more than fifty years, painters have been using rollers. Rollers have a number of advantages over brushes and aerosols. They are especially good at processing large surfaces. Let's try to figure out how to choose the right roller in each case.

Price list

Roller long blonde, sponge

311 rubles.

Roller oval dark brown, art.volume + mesh

131 rubles.

A set of mini rollers "POROLON", 100 mm, D - 35 mm, D handles - 6 mm, 10 pcs. + 2 braces // SPARTA

The set includes rollers made of polyurethane foam (foam rubber).

271 rubles.

Needle roller for bulk floors, 400 mm // Russia

It is used for the production of self-leveling floors, preventing the appearance and removal of air bubbles, and also for leveling the surface layer.

476 rubles.

The triumphal procession of platens for paintwork and the conquest of the most diverse areas in the professional activity of painters, furniture makers, builders and repairmen is explained very simply. Brush and roller of the same width with one-time dipping in paint or varnish can cover quite the same area. Try yourself to conduct such an experiment. And you will be convinced: the area covered with paint with the help of a roller will be three to four times more than the surface treated with a brush. Not to mention the convenience of the painting itself. Working with a brush, the paint must be "stretched" over the surface, thus achieving its uniform distribution. With a roller this does not have to be done. Comparing the quality of the work done, one can only wonder how much more smooth, uniform surface the work roll provides. With the same effort, you will do more work, in other words, the efficiency roller is immeasurably higher.

Another advantage of this

- the possibility of applying an even layer of paint or varnish on a structured surface, for example, on corrugated wallpaper. Working with a brush on a similar plane will lead to an excessive accumulation of coloring material in each notch, which inevitably worsens the quality of all work. The roller - with its uniform adhesion to the plane - as it distributes the paint itself: where it needs to be wetted, in other places it cleans.

In addition to all these obvious advantages, the rollers allow you to perform operations that are simply beyond the power of the facade brushes or maklovitsam. Namely: you can create a variety of special effects with rollers. Let's say, having covered with a varnish any smooth wooden or plastic surface and having waited till half-drying of the put layer, it is possible to walk a little on it a platen once again. As a result,

- Under the orange peel. Or - on the corrugated wallpaper, painted with water-based paint, slightly walk through the roller with a paint of a different color. If you do this carefully, without pressing the roller tightly against the wall, you will get corrugated multicolored wallpaper: the recesses will be the same color, and the bulges will be the other.

The material of rollers, which are available in Ukrainian building supermarkets, can be very different. The choice of a suitable tool depends solely on the nature of the upcoming work.

At first the rollers were made only of natural sheepskin. However, later it was replaced by modern substitutes. Such materials cost much less than natural sheep's fur, and besides, they provide the best quality in work. and the walls can be used from sheepskin. However, it is not worse (and in some cases better) for the quality of the treatment when working with nylon plush or foam rubber rollers. For application made on the basis of synthetic resins, it is necessary to use a mohair roller. An excellent result brings work rolls made of foam rubber, although their price is much lower than that of rollers made from natural and other artificial materials. Foam rolls can be used when working with water-based, oil and acrylic paints and varnishes. The only thing you need to remember: foam rubber rollers for working with lacquers should be smaller and thinner than foam pads for working with water-based materials.

Rollers of various sizes are produced: the width can be from 5 to 30 cm, the diameter is also different. When choosing, you need to use a simple and natural rule: the larger the surface to be machined, the larger the diameter and width should be the roller. However, with and ceilings, it is better not to use too wide ridges, for example wider than 30 cm. The reason for the restriction is considerations of basic convenience. The wider the roller, the more paint it absorbs into itself, hence the more it will increase its weight. When working with such a roller you will have to make considerable efforts, which can lead to rapid fatigue, pain in the hands, and as a result - to the total inability to continue working. In this case, it is better to have a precaution in stocking the extensions for the handle. Especially it is convenient when painting high walls or ceiling. A telescopic (sliding, adjustable) handle is attached to the roller - and the problem of high ceilings is practically solved.

Diameter of the roller should be selected, based on the volume of the surfaces to be painted. The larger the diameter of the roller, the more naturally the paint material absorbs into itself when it is lowered into a container with paint, and the larger the surface can be painted with it.

When buying a tool, you can purchase several replacement rollers to one handle. If the rollers are worn out and the handle is left, grab it with you to the store and pick up the replacement element under its width.

When choosing a tool for future paint and varnish work, in addition to the surface to be treated, it is also necessary to take into account the presence of difficult or hard-to-reach places. You may need a brush. Even a few. To paint inside the radiator of water heating is one thing. This requires a radiator or curved brush. And paint the corners, which could not be processed with a roller, - quite another. Here you can use a skewed brush. However, on sale there are special tools, for example, for painting walls behind heating batteries. Such rollers are made of a small diameter, and the handle is necessarily long. For painting various rounds and pipes, a tool is used, the roller of which consists of several narrow ridges strung on the curved rod of the handle. The corners can be painted with rollers of another shape: narrow, large diameter, with a long soft pile. With paintwork, you are bound to encounter several border areas. The boundary surface can either not be painted over with a roller, or it represents a transition from one color to another. In such cases, you will be helped by brushes or special pads with short mohair pile. When working with such pads, remember: dipping them in the paint can only be a few millimeters.

We choose the platens for painting

We choose the platens for painting

For protection of palae and furniture, polyethylene film or paper can be used in rolls

The design of the rollers, no matter how simple it may seem at first glance, can significantly affect the quality of work, which determines the scope of this roller. We have already said that the diameter of the rollers can be different. The length of the pile of the roller can be different.

The longer the pile, the more paint can absorb the roller and, therefore, the thicker will be the layer of paint on the surface to be coated. Usually the long nap has a thicker own thread, the short one is usually smaller. Thus, the rollers will differ from each other by the graininess of their surface. It is clear that a coarser pile will give a thicker layer of painting, and a shallower layer will be thinner. To further increase the amount of paint inside the roller, the designers applied a so-called soft base or lining. In such a roller, not only the working surface, but also its internal part, accumulates, and then gives off the paint. It is enough to apply a small force to the roller, and the lining will provide the surface to be treated with an additional portion of the paint material. The diameter of such a roller, naturally, is more than usual and it looks quite amusing - just like a small pillow. But for one dipping in the paint it is able to paint a much larger area than the ordinary roller.

Roller with a suitable mesh scraper made of plastic or metal

A metal or plastic grating is hung on a container with paint

Pillows with short pile are convenient for painting ceilings

The longer the pile of the platen, the more it deforms during work: it bends, it is laid with uneven patches, it breaks. In order to get rid of such phenomena, manufacturers began to weave metal threads into the material of the working surface of the rollers. These rollers are called "golden thread". Metal strengthens the surface of the roller, gives it additional density and stiffness. Metal strips are woven into the material of the roller in different ways: perpendicular to the direction of movement of the roller or at an angle to it, forming a screw line on the platen. Naturally, the service life of such tools is significantly increased. However, like the price.

Rollers for ceilings: one with a tank, the other with a stop

Rollers for painting ceilings may have an additional trough, permanently attached to the axis of the roller. In the trough, excess paint will drain if you accidentally take it on the roller too much. This simple device will give your work extra comfort and will allow you to perform it carefully. At the end of the work, you do not have to wash the overalls. However, it is better to protect the floor and furniture when painting works. This can be done with a polyethylene film or paper cloth. However, ordinary newspapers successfully replace any professional protective materials.

For painting window frames it is most convenient to use rollers with limiters. Especially they are convenient if you decide to paint the frame with paints of different colors. A curved strip of metal is attached to the handle of the narrow roller, the end of which has a small metal or plastic plate. This plate protects perpendicularly adjacent surface from the paint applied during operation. Thus, this tool enables each surface, located in a different plane, to paint in its color.

Limiters can be and at platens for painting of equal surfaces. They are arranged a little differently. On the metal or plastic plate there is a small brush, which during operation limits the spreading of the paint. It seems to clean it up. However, it is not necessary to use special limiters. It is cheaper and easier to buy a paint tape and stick them in places where there should be a flat border. We guarantee that you will get an accurate and precise contour. If you want to extend the handle of the roller, you can purchase telescopic rods, which are attached to it. The rods are available in different designs: fiberglass, aluminum and metal with plastic coating. Some of them, as we have already said, have a tank for paint. Paint is supplied by turning the tubular regulator.

Numerous adaptations and accompanying tools for roller work include: grating; baths for paint; a rigid brush; , brush-flutes and so on. The grate can be made of metal or plastic and serves to wring out excess paint by rolling the roller along the grate. This operation also promotes better impregnation of the roller with paint. With the help of a small hook, the grating clings to the paint tray. In order for the mesh not to get stuck in the bath, it should be a bit already its internal size.

However, we advise you to purchase all the necessary tools in the kit. This will cost less, and does not require mutual "fitting" of devices. Moreover, everything you need is on sale: from a simple set (bath, roller and grill) to a paint set consisting of 16 items, including replaceable rollers.

Artistic and decorative painting works can also be produced by rollers. But this requires either a stencil or a special, relief tool. Stencils can be made by yourself - it would be time and desire. While holding the stencil with your hand on the wall, you can apply paint with the other hand. It is desirable that the stencil depicts individual objects. In this case, the boundaries of the stencil overlay after painting will not be noticeable. By the way, it is the rollers that are most suitable for working with stencils. Even using aerosol can not achieve the same quality as when working with rollers. The reason is that the roller not only paints the pattern, but also presses it, making the outlines of the pattern more clear. While an aerosol jet can easily penetrate the gap between the wall and the stencil, than it will wash out the line of drawing. The embossed rollers are made of genuine leather or sponge, soft plastic or foam rubber and have a structured surface. The pattern on the roller determines the artistic pattern, and you can choose the color and paint yourself.

During short breaks in the work, so that the paint on the roller is not dried, we recommend dipping the roller in the paint and wrapped in an airtight film (for example, in a plastic bag).

Removable rollers of different sizes are convenient for complex painting

Rollers with long handles for pipes, corners and hard-to-reach places

After finishing work, the roller must be freed from paint or varnish. Roll it several times on the grid, thus removing the paint. After that, the oil or acrylic materials are removed by appropriate solvents. However, the consumption of the solvent can be so great that it is cheaper simply to throw out the roller, replacing it with a new one. Roller, which you applied water-based paint, thoroughly wash in large quantities of water. It is desirable that the water was pressurized. After washing several times shake out the rests of water from the roller and hang it to dry. We do not recommend to twist the platen - it can lose shape. Since you will not be able to shake out all the water, place a container under the suspended roller, into which the remaining water will flow. We wish you an easy, pleasant and fascinating work, the results of which will satisfy you and your whole family.

Advantages of roller painting

Advantages of roller painting

By painting a large area of the ceiling with a roller, it is easy to avoid an uneven accumulation of paint in certain areas. I work with brushes, it's almost impossible to get a uniform layer.

In addition, it is through the roller that you can achieve interesting visual effects on the surface. For example, if painting of the ceiling with relief wallpaper occurs, you can walk along the already painted surface with a paint of a different color.

In this case, the roller does not need to be pressed tightly, then it will only paint the top of the surface, and the cavities will remain the same color.

The most common types of rollers are products made from natural sheepskin, foam rubber, nylon plush, mohair.

Cushions of sheepskin, of course, are good, but their cost is high enough. A perfect analog, these are rollers made of foam rubber or nylon plush. They can equally well handle both, and the ceiling. Optimal paint, it's acrylic, oily, water-emulsion.

With paints that contain synthetic resins, it is best to work with a mohair roller. Its cost is quite low, and as a result there will be a beautiful and evenly painted ceiling.

Various properties of the roller are also due to the length and diameter of its pile. Naturally, those tools in which the nap is wide, give the ceiling a coarse-grained pattern. Rollers with a small diameter of the pile make the texture of the ceiling almost without grains. And of course, the more hairiness, the more paint it will absorb, and hence the layer will be thicker, stronger.

In some types of rollers, not only the outer part collects the paint, but also the inner one. Due to this, when painting the ceiling it is not necessary to dunk the roller so often into the bath. Since the inner part of the roller, absorbed the paint stock, with a slight pushing the material falls on the ceiling. Thus, for one approach, such a roller will cover a larger area than a normal one.

A more expensive type of roller with a long pile, this is a "golden thread". To make the long pile less deformed, it is reinforced with a metal thread, over the entire area of the roller. Such a tool lasts longer, but its value is higher.

And the last type of roller, designed for decorative, with a painting pattern. It has a certain relief pattern and is usually made of leather, soft plastic. When rolling on the wall, the relief lines of the instrument create a unique pattern.

Thus, choosing a roller for painting, you can choose it for any type of paint, taking into account the features of the room.

How to check the quality?

In a good ridge, threads and villi do not stick out, the seams do not protrude above the level of the roller, otherwise the staining can not avoid traces. The working surface of the roller is neatly sewn.

Also the source of information is the strips on the platen. If they are located along the roller, it means that the cover is sewn and it can be changed if crosswise or obliquely - the cover is glued and can not be replaced. The more strips, the more resistant the roller to an aggressive environment.

Typically, a regular roller is equipped with a handle, the length of which is 30-50 cm. For painting and the top of the walls, as well as for working with the floor, it is convenient to extend the handle. For this purpose, special extension pins are used, the length of which can be up to 4 m, and the design - telescopic.

To ensure the roller lasts long, after use it must be washed with warm water and soap or solvent.

Classification

By material

Foam are suitable for working with varnishes, waterborne paints, water-based adhesives, primers. Not suitable for emulsion paints, since air bubbles, which are formed when applied with a foam rubber roller, subsequently burst and make the surface to be painted uneven. Wear such rollers quickly.

Velours allow you to apply paint evenly and smoothly. Suitable for work with emulsions and oil paints, however, due to their high absorbency, they require frequent immersion in the paint.

Fur perfectly distribute the paint on the surface, suitable for enamels and oil paints. For relief surfaces, you need to select a roller with a long pile - the more pronounced the relief, the longer the pile should be.

Threaded. Of the advantages - do not leave villi, well washed after use. Threaded rollers require careful work, as they spray paint.

By appointment

Are intended for drawing of drawing on a painted surface. Depending on the type of roller, a variety of effects can be obtained. With the help of such a roller, both textured plaster and decorative paint are applied.

For wallpaper. For glue application - foam rubber, for smoothing of wallpapers and removal of air bubbles - rubber, for painting of wall-paper - the roller with a pile of average length.

For facades. Such rollers have a special padding in the intermediate layer. To prevent the paint from splashing, the facade rollers are provided with special bearings that slow the rotation process.

Painting walls, floors, ceilings and other elements of the house or apartment can be different colors and different tools. One of the most popular and common tools for applying paints is a paint roller. About him our today's story.

There are many varieties of rollers and each of them has its own purpose and differs from others in appearance - the material and the size of the fur coat.

Immediately specify all the terms that we will have to use in the process of this story. A roller is a part of a tool consisting of a plastic, wooden or aluminum cylinder with a soft coat on it that absorbs the paint and then, when rolling, applies it to the surface to be painted. The familiar design of a handle and a curved metal rod (clasp), on which the roller is mounted - is called a machine or simply a handle.

Cushions of rollers for simple work (from left to right): Anlon, Elon, Polyfoam, porous, Polyfoam, Perlon, Dylen, Polar

It is important, apart from the terminology, to know the generally accepted classification of rollers, so that when you buy the letter on the price list you do not seem to be Jewish. Domestic rollers are divided into four groups, each of which has its own marking. The first letter is always B, which means the platen. The second designates the material from which the coat is made, and if there is a third letter, then this is the field of application.

The first three groups are designed for application on the surface of paint and varnish compositions.

VM - rollers with fur coating,

VMP - rollers with fur coating for painting floors,

WMU - the same rollers, but intended for painting concave angles.,

EaP - rollers with polyurethane (foam rubber) coating for work with water-adhesive compounds.

Materials of fur coats for paint rollers (from left to right): Rylon, Rylon, Sheepskin, Mohair with short nap, Terry cloth, Felt, Foam

According to the rules, the fur coating for the roller should be made of sheepskin or silk base, covered with a pile of chemical threads.

Recently, a lot of imported rollers have appeared on the market. Their range is so great that the choice sometimes puzzles even an experienced specialist. Difficulties are added by the fact that each country of the producer has its own way of classifying.

For example, manufacturers of Finland divide rollers into seven groups:

Mini - rollers are mainly used for painting small or hard-to-reach surfaces, including corners.

Midi - rollers - one of the most common types of painters' painters.

Difference between universal and professional rollers is very conditional: the criterion for this division is usually the quality of the fur coat and the diameter of the rod. For professional tools is characterized by a higher quality material, and the diameter of the rod from 9mm.

Facade rollers characterizes the presence of an internal intermediate packing and a more perfect system of bearings. Thanks to it and the increased diameter, the roller rotates more slowly than usual and when working with such a tool, the paint is sprayed much less.

Wireframe rollers They are very convenient in work, since they easily curve around irregularities. In addition, they are 20-35% cheaper than traditional platens. The peculiarity of these rollers is indicated in their name: the coat is not worn on the cylinder, as in the rest, but on a special frame made of wire or polymer. Unfortunately, they are still little known in our country.

Special rollers are divided into rollers for floor, wavy surfaces, aggressive and structural materials, lamination and for wallpaper rolling.

But one of the leading manufacturers of tools for painting works - the Swedish company ANZA uses a different classification. In size, these are three groups: mini, midi, maxi-rollers.

And on the application of five groups:

high-quality PERFECTA;

for all types of repairs (floors, walls, ceilings);

for varnishes and enamels, when a very smooth surface is required;

special

for simple work

In addition to the dimensions of the paint tool, you need to pay attention to the material from which its coat is made. Here, the situation of choice is further complicated and confused by the fact that for the name of the same material, each firm uses its own symbols.

Here are the main groups of materials for fur coats and some of their names used by Finnish firm Sakeva.

group PE - polyester (polyester): foam rubber (molotoprene), vestan (artificial fur), yellow vestan (reinforced),

group N - natural materials: sheep's fur, llama, goat, velor, mohair, felt, rubber

pC group - polyacryl: kanecarone, modacryl, meril;

group of RA - polyamide: perlon, nylon.

Even fur coats made from one material can differ among themselves in other parameters. Here are some examples of this.

Mini-rollers are made of several kinds of foam rubber: normal and high-flying with a density of 30 and 60 kg / m3, respectively. Naturally more dense roller serves longer.

Foam rollers, Used for high-quality varnish painting with water-dispersion paints, they are available in two colors: dark blue (top quality) and thick yellow color.

Polyacrylic rollers from a material called melir, imitating a lamb's fur, are issued in three colors (in order of increasing quality): blue, yellow and light green.

Perlon rollers (polyamide) are white, light yellow and light green in color.

When choosing a roller, in addition to the material of the fur coat itself, you should pay attention to its compatibility with the paint and varnish material that you are going to use.

The stability of the coat to the effects of paint can be judged by the strips applied to it - the more of them, the more resistant the material to aggressive substances. In addition, the strip can determine the method of its manufacture and replaceability. If the stripes on the fur coat go along the roller - it means it is sewn and it can be replaced. If they are located across or obliquely, the coat is glued and can not be replaced.

Most of the fur coats for mini and midi-rolls are glued. They are not very durable, as paint and varnish materials quickly destroy glue. But there are pluses. The process of their manufacture is quite simple, and consequently - these rollers are cheaper than others.

Fur coats for universal, professional, facade and special platens, as a rule, sewn. They last longer and, if necessary, they are replaced with new ones.

Separately, in our opinion, it is worth mentioning the so-called texture rolls (for creating textured surfaces). They are produced quite a lot of varieties, each of which is designed for a certain type of work with textured finishing materials, and many other options.

In order to be sure. that you acquire a quality tool, be guided by the availability of an international quality certificate ISO9001.

In conclusion, we note some features of machine tools (handles) for rollers. They differ not only in size of the yoke, but also in the total length. There are short - 30 cm, medium - 35 - 45 cm and long - from 50 cm. If the fact that you need to paint is far away, it makes sense to buy a special handle - an extension cord. The length of the extenders extends from 0.7 to 4 m.

There are several other elements that are designed to make your work with the roller more convenient and qualitative. Many firms produce special pallets, kits consisting of a roller with a pallet, roller stands and scrapers for cleaning. The pallet provides a place where the paint is poured and the surface on which you can roll the roller to achieve its uniform impregnation.

In short, before you start using the paint to turn your apartment into a palace, do not be lazy to spend time and choose the right tool, and then the work will give you pleasure.

Based on the materials of the magazine "Ideas of your house"